Static LED Markings & Signs

Most workspaces do not require dynamic markings, so static outputs projected using LED technology can be used here. The same advantages of lighting technology compared to conventional floor markings also apply here: no wear and tear caused by dirt, friction, weather or even extreme temperatures of up to -30 degrees Celsius.

LED technology is significantly cheaper than laser technology (projectors start at €500) and much easier to handle. Safety-related aspects, as with laser technology, are not an issue here!

Our LED projectors for floor markings can be operated 24/7 for up to 4 years at a time (realistic – not peak) before the performance of the LED panel in the projector decreases. The running costs are also very manageable, as the projector’s LED panel can be easily changed individually at the end of the term. Since our projectors are passively cooled and therefore do not require moving fans, they do not require any special maintenance. Last but not least, the IP65 protection prevents moisture or dust from having a negative impact on the electronics.

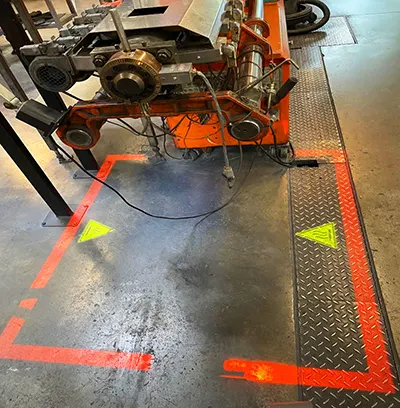

In the following example you see 2 different types of projection – an LED line projector (projects the green line) and an LED area projector (projects the „caution forklift“ symbol).

We basically differentiate between 2 types of projectors.

Our line projectors project a marking line in the color and length you require onto any type of surface. Depending on the projection lens used, the projector creates a line on the floor that is up to twice as long as the distance from the projector to the floor. Line projectors are available with 80W and 150W output power, to individually serve differently illuminated areas. From January 2025, color-changing line projectors (red-green-yellow) will also be available.

Our area projectors project any desired output, within a specific radius, downwards onto the floor or onto a wall. The size of the output (diameter) depends on the installation height and the lens used. You can find a calculation here. Warning and information signs are common outputs, as are pallet parking spaces and zebra crossings. The required projector power depends on the ambient brightness, the floor conditions, the desired output size, and the output color—which is why we offer a total of five power classes.More about the surface projectors below.

While yellow is the most common color for marking lines and walkways in logistics halls…

…green is the most visible color to the eye, which is always clearly visible even in high ambient brightness and on almost all types of floors. This becomes very clear in the following picture, when we installed 2 line projectors in a row at the customer’s in a very brightly lit hall. The output from both projectors results in a pretty impressively long line – seamless!

In the following you can see the „underground“ use of our 80W line projector, which outputs a blue dividing line. Although the projector is hung directly in a row with very bright LED lamps, the line can still be clearly seen even in poor ground conditions. We deliberately show you issues under difficult conditions, even if that is not usually the case.

The conditions for the red dividing line are almost optimal here.

The handling and installation of line projectors is simple and straightforward. They work in any type of hall and on any floor type. Feel free to share information about your location with us to receive a professional quote.

An area projector can, as the name implies, display an area of a predetermined size and any type of output on the floor or on a wall . After the output has been determined, usually through a graphic (image), the optics are milled accordingly and inserted into the projector by us. Simply put: Whether you want to issue a warning sign, your company logo, or whatever your desire is – everything is possible! You can see some examples here. The maximum possible output size depends on the respective installation height.

In view of the fact that „all customers“ have different installation environments, it goes without saying

Each time, relevant information is exchanged so that every customer can receive professional advice and service. At this point it should be said that we only offer projectors for sale if the customer ultimately receives the output in a way that meets his requirements.

In the research hall of the Fraunhofer Institute in Dortmund, where our laser technology is also installed, we tested our projections on different floors under various lighting conditions and with different powers.

Due to the very high workload of our company, as well as to protect our projectors, we do not accept customers who are interested in individual projectors – with exceptions for pilot projects.

We ship our products exclusively to end users – not to resellers or system integrators. This ensures that all customers have direct access to our team and our expertise. Products can be purchased through third-party suppliers if you don’t want to list us as a supplier for a few projectors.

Our projectors can be controlled simply via switches, but also via your own CAN BUS system. All LED floor markings can be monitored using light barriers, radar or infrared motion detectors. A separate control module can be used to output a visual warning (e.g. flashing of the projection). Last but not least, you can also control the projectors in a modern environment via Internet/Wifi.

Here is an example of a modern, intelligent sensor control that can differentiate between people and vehicles if desired. Whether you use it to control a goal, our projectors, or both is up to you.

Current information:

Due to the very high workload of our company and to protect the product of our projectors, we do not accept customers who are interested in individual projectors.

2 line and one area projectors in use.

Comparison of well-preserved, conventional floor markings with a modern, „projected“ LED marking.

Comparison of yellow, worn, conventional floor markings with a modern, „projected“ LED marking.

Green and yellow line projection in direct comparison:

The lines of two projectors merge seamlessly.

Blue line projector on dark floor.

Installation of red LED floor markings

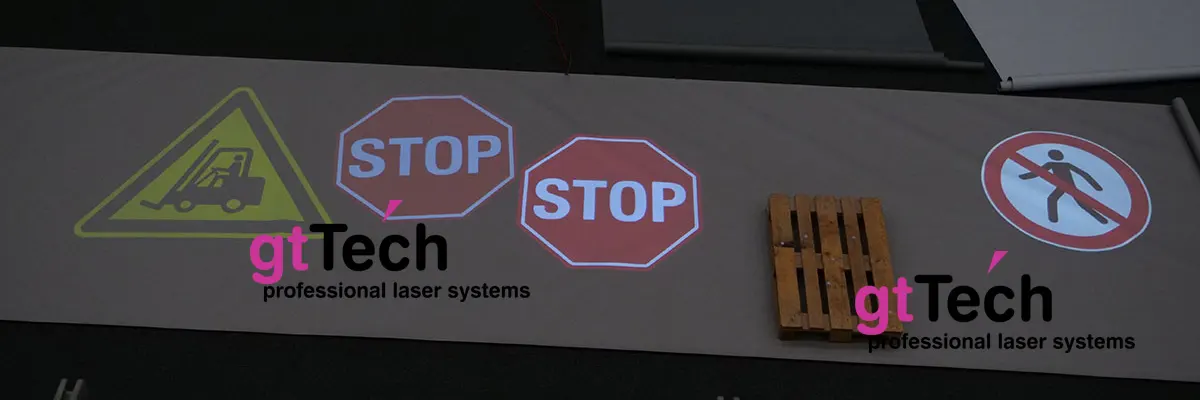

Example of projected information signs.

„Be careful with forklifts“ on tar ground:

Projected stop sign with only 60W output power:

Issue on sandy soil

Red heat warnings!

All of our projectors can be controlled via intelligent sensors.