Dynamic Laser Markings

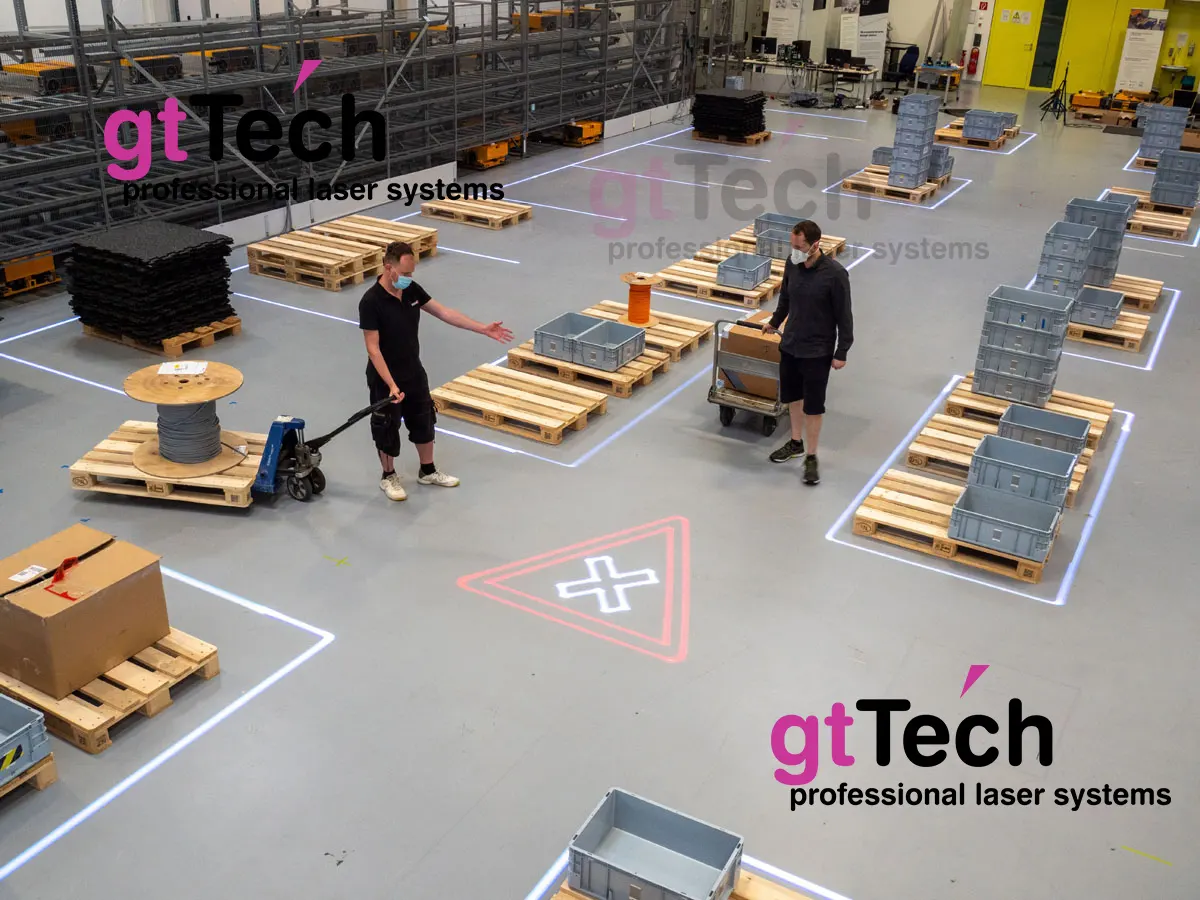

In warehouse, production and shipping, order and clarity are the key to efficiency. Carelessly parked pallets or packages, routes too close to machines or unclearly regulated crossroads for employees walking and conveyor vehicles: all of this disrupts operations in a very sensitive way. Consistent floor marking for warehouses and industry indoors and outdoors supports efficient operational processes and helps to avoid accidents and reduce costs.

The interlocking of different processes in different areas is becoming increasingly important. Companies have to find a way to optimize the efficiency of their own work processes. In the case of forwarding and logistics companies, this efficiency can be achieved by means of dynamic logistics marking. Marking of traffic routes for industrial trucks and guide markings on flight operations also make a significant contribution to the optimization of workflows and operational processes.

Floor and logistics markings not only serve to optimize processes, but also increase the safety of traffic routes both outside (lanes, loading zones) and inside (warehouses, halls).

In the case of sealed industrial floors, floors mixed with paraffin, sanded floor surfaces, epoxy-coated floors, bituminous surfaces, antistatic surfaces and alkaline substrates such as paving stones and concrete ceilings, the choice of the marking material to be used had to be made in With regard to the durability and the bond adhesion have so far been taken very carefully.

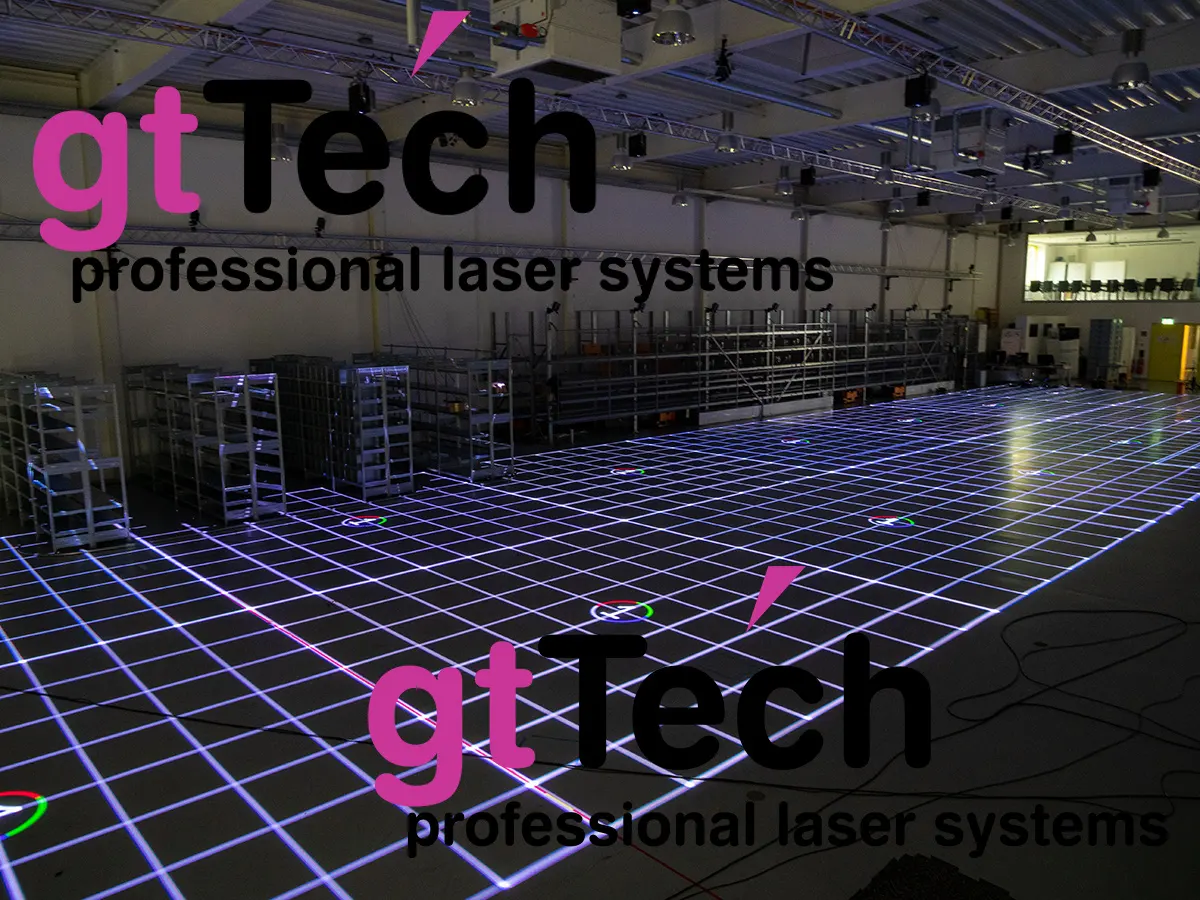

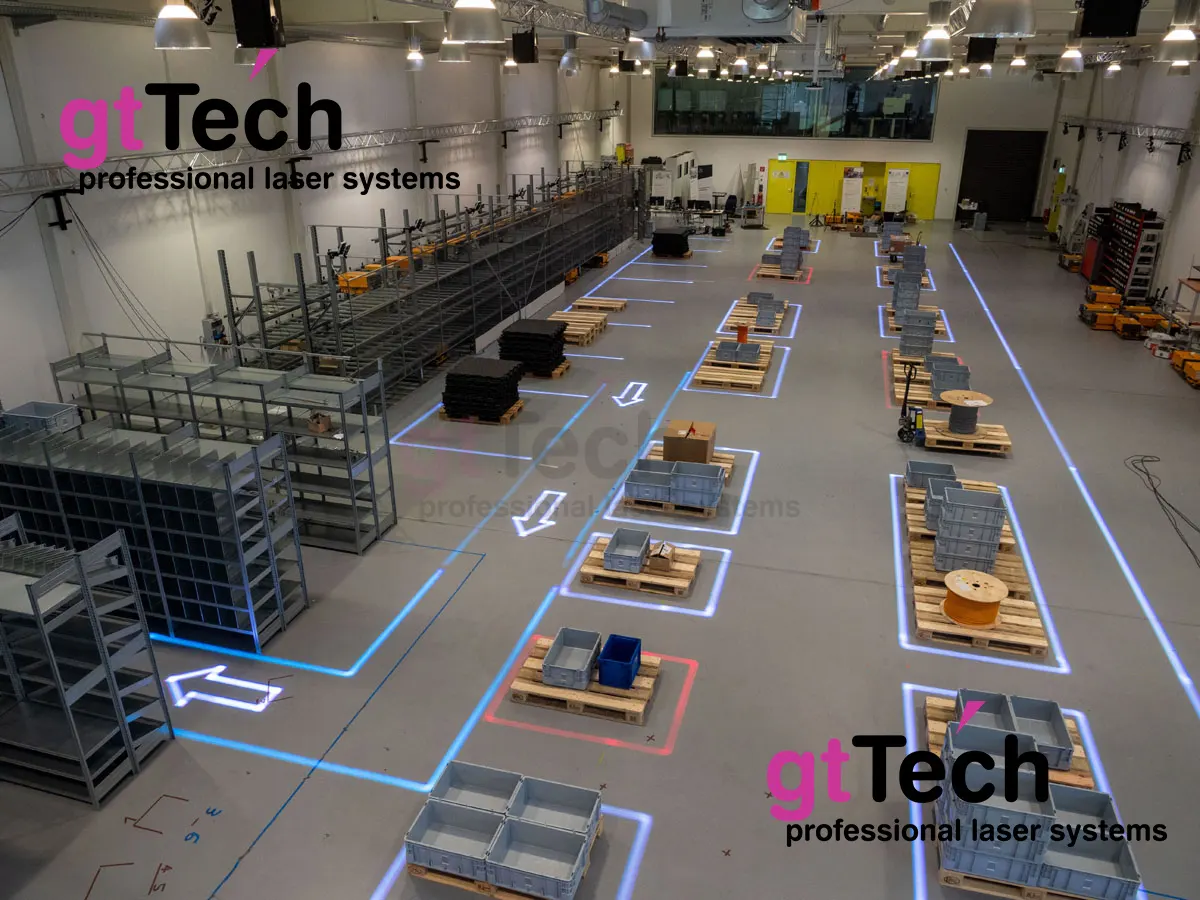

Our goal is to use modern lighting technology (laser & amp; LED) to create „dynamic“ floor markings that are not worn down by dirt, friction or weathering. Our light sources can be adapted to different and / or changing needs at any time in terms of color, shape and orientation! For example, each layer can use its own light profile.

A dynamic labeling of logistics parking spaces using lighting technology not only creates additional space, but also optimizes work processes and thus saves time and money. Logistics processes are accelerated considerably and search times are reduced.

Of course, it should not go unmentioned that we had the laser output in the test hall of the Fraunhofer Institute for Material Flow and Logistics in Dortmund approved by TÜV Süd Industrie Service.

The following two videos provide an overview of the use of our new technology. This can be inspected on site after consultation and an appointment with us in the research hall of the „Fraunhofer Institute for Material Flow and Logistics in Dortmund“.

• Not tied to the ground

• Insensitive to soil pollution

• Brightness stability (up to 1,200 lux, average ~ 700 lux)

• Temperature resistance

• Dust resistance

• dynamic change of the display in real time

• No tracking technology required

• Cost savings due to increased process efficiency, reduced search effort, fewer damaged goods, fewer work accidents

• Laser output can be approved by TÜV